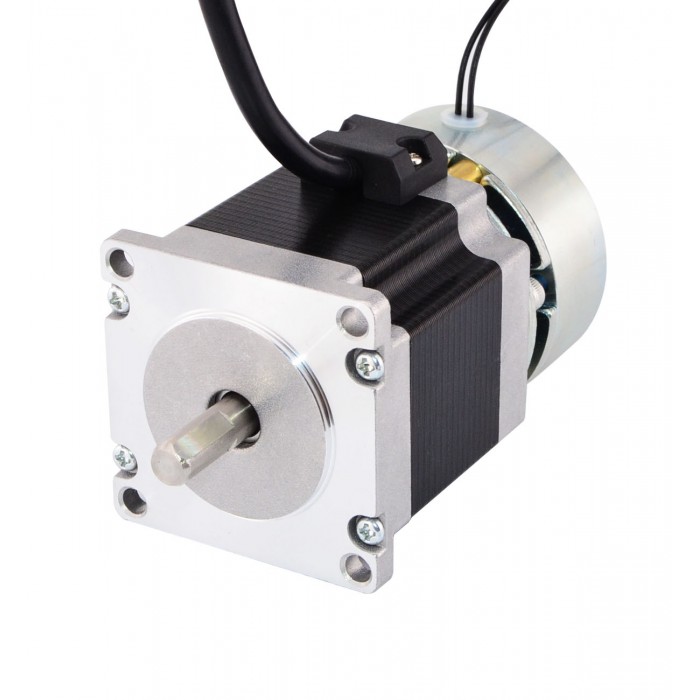

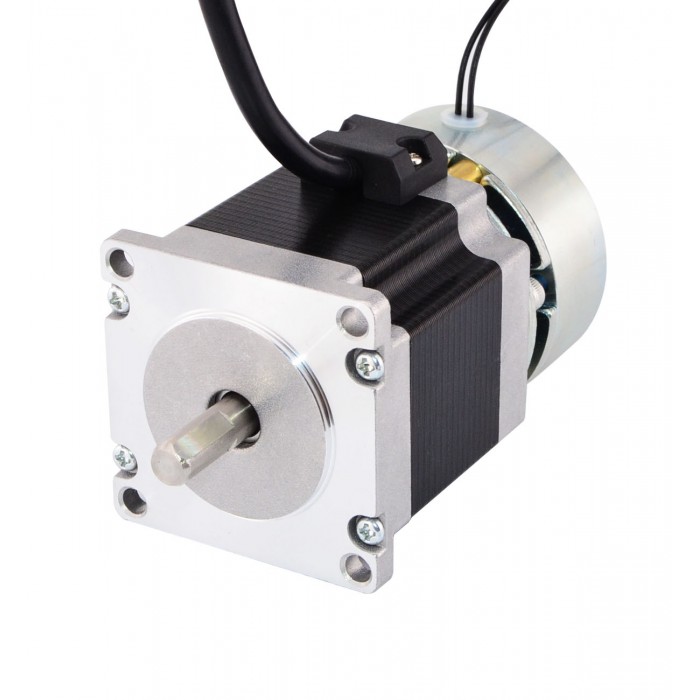

Small stepper motors pack a punch despite their limited stature. Such motors are well known for their excellent open-loop positioning characteristics and for delivering relatively high torque, but even higher performance can be achieved with an often overlooked configuration. Fitting a gearhead to a stepping motor can increase torque and resolution, reduce vibration, and let a relatively small motor drive large inertia loads.

When a gearhead is added to a stepping motor, the increase in output torque can be calculated by multiplying the motor torque at the desired speed times the gear ratio times the efficiency of the gearhead.

Tout = Tmotor x i x η

where

Tout = output torque at gearhead shaft

Tmotor= output torque of stepping motor

I = gear ratio

η = gearhead efficiency

All stepping motors have a resonant frequency in the 150 to 300 steps/sec range, which can cause the motor to vibrate or miss steps. Adding a gearhead can reduce this vibration. In order to obtain the same shaft speed, the frequency of the input pulses needs to be increased. After increasing the input frequency, the motor will no longer operate within the resonant frequency range and will run more smoothly.

Inertia basically determines how quickly a load will accelerate or decelerate. In general, it is recommended that the ratio of load inertia (reflected to the motor shaft) to the rotor inertia be 10:1 or less. The more quickly you intend to accelerate or decelerate, the lower the ratio should be. A gearhead reduces load inertia reflected to the motor shaft by the square of the gear ratio. For example, if a load has inertia of 1,600 oz-in.2 and a 7.2:1 gear ratio is used, the inertia reflected to the motor shaft will be 30.9 oz-in.2

Jref = Jload/i2

where

Jref = reflected inertia at the motor shaft

Jload = load inertia

I = gear ratio

The gearhead ratio also has an effect on step resolution. For example, a 7.2:1 gearhead attached to a stepping motor that moves 0.72°/step would have step resolution of 0.1°/step at the gearhead shaft.

Resout = Motorres/i

where

Resout = resolution at gearhead shaft

Motorres = motor resolution

i = gear ratio of gearhead

No free lunch

Of course, you don’t get something for nothing. There are some tradeoffs when a gearhead is used, such as reduced output speed and positioning errors in the mechanical system. The speed of the gearhead shaft is reduced by the ratio of the gearhead.

Select figure to enlarge.

Ngear = Nmotor/i

where

Ngear = speed at gearhead shaft

Nmotor = motor speed

i = gear ratio

When a gearhead is added to a stepping motor, the increase in output torque can be calculated by multiplying the motor torque at the desired speed times the gear ratio times the efficiency of the gearhead.

Tout = Tmotor x i x η

where

Tout = output torque at gearhead shaft

Tmotor= output torque of stepping motor

I = gear ratio

η = gearhead efficiency

All stepping motors have a resonant frequency in the 150 to 300 steps/sec range, which can cause the motor to vibrate or miss steps. Adding a gearhead can reduce this vibration. In order to obtain the same shaft speed, the frequency of the input pulses needs to be increased. After increasing the input frequency, the motor will no longer operate within the resonant frequency range and will run more smoothly.

Inertia basically determines how quickly a load will accelerate or decelerate. In general, it is recommended that the ratio of load inertia (reflected to the motor shaft) to the rotor inertia be 10:1 or less. The more quickly you intend to accelerate or decelerate, the lower the ratio should be. A gearhead reduces load inertia reflected to the motor shaft by the square of the gear ratio. For example, if a load has inertia of 1,600 oz-in.2 and a 7.2:1 gear ratio is used, the inertia reflected to the motor shaft will be 30.9 oz-in.2

Jref = Jload/i2

where

Jref = reflected inertia at the motor shaft

Jload = load inertia

I = gear ratio

The gearhead ratio also has an effect on step resolution. For example, a 7.2:1 gearhead attached to a stepping motor that moves 0.72°/step would have step resolution of 0.1°/step at the gearhead shaft.

Resout = Motorres/i

where

Resout = resolution at gearhead shaft

Motorres = motor resolution

i = gear ratio of gearhead

No free lunch

Of course, you don’t get something for nothing. There are some tradeoffs when a gearhead is used, such as reduced output speed and positioning errors in the mechanical system. The speed of the gearhead shaft is reduced by the ratio of the gearhead.

Select figure to enlarge.

Ngear = Nmotor/i

where

Ngear = speed at gearhead shaft

Nmotor = motor speed

i = gear ratio

No comments:

Post a Comment